RBI methodology is applied for all the pressure containment equipment whose integrity may be gradually deteriorated by ongoing damage mechanisms. In short, RBI addresses the failure mode of a pressurized equipment - 'fails to contain' due to failure causes such as general, localized corrosion, stress corrosion cracking and other degradation mechanisms.

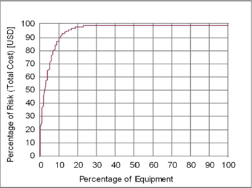

RBI is a method that uses 'risk' as the basis to prioritize and manage the efforts of an inspection program. An effective RBI program results in reduced level of risk for a given level of inspection activity. In any operating plant, a relatively large percentage of the risk is usually associated with a small percentage of equipment. This risk profile of a facility can be illustrated in a plotted curve, which is termed as the Pareto Curve.

% of Equipment vs % of Risk (Pareto Curve) |

RBI methodology permits the shift of inspection resources to provide a higher level of coverage on the high risk items and an appropriate effort on lower risk equipment. In other words, RBI is a tool to locate and schedule inspections on the basis of the degradation mechanism. RBI results help develop inspection plans, while the results of inspection execution & evaluation are fed back to the RBI for updating of risk. This is an ongoing process throughout the life cycle of the asset covered under RBI.

Risk is defined as

RISK = Probability of an event (PoF) x Consequences of that event (CoF)

PoF can be estimated by historical data, calculation of degradation and by expert assessment. Probability can be given in terms of a ranking, e.g. low, medium, high (qualitative) or as likelihood of the event per year, e.g. 5.4x10-3 (quantitative).

CoF can be assessed in the areas of

- Safety - Injury, loss of life

- Environmental - damage to the environment

- Economic - business interruption, financial loss from lost production, damaged equipment

- Reputation / Political - adverse publicity

Consequence can be given as a rankling, e.g. minor, major, catastrophe (qualitative) or in quantitative terms such as;

- Safety (PLL) = 1.2x10-4

- Economic = US$500x103

RBI works by assessing the consequences of failure and the probability of failure separately for each item (every equipment and piece of piping). The product of CoF and PoF gives the risk evaluation and the risk assessment results for the individual pressurized item (piping, vessel etc) can be presented in the 5x5 matrix as shown below.

The risk associated with the process equipment is not constant since the process is dynamic. Hence a quantitative approach to RBI enables updating the risk profile and revising the inspection programs. Qualitative approach can be likened to a snap shot by a camera which gives the risk profile at the time of study only.

As discussed, RBI deliverable is primarily an inspection program and the guidance on 'what to inspect?', 'when to inspect?', and 'How to inspect?' that is depicted in the following figure.

AGT's RBI consultants have more than 10 years experience in executing Risk Based Inspection programs for various industries. |